COMPANY

We are a specialist power spring manufacturer located in Taiwan, Asia.

● Our characteristics:

Meta Spring Industry Company is a leading manufacturer specializing in high performance Steel Strip Springs.

Established in 1975, we specialize in providing strip springs manufacturing and engineering support for a variety of industrial applications, including medical devices, industrial applications, consumer products, sports equipments, and automotive and transportation applications.

Click here to find applications of springs.

As a leading spring manufacturing supplier we creates a comprehensive quality assurance system from raw materials to every single spring and spring assembly delivered to our customers. We develop our own spring coiling and processing equipments and spring assembly machines to ensure product stability and quality. We are proudly to meet all your needs of strip springs for constant force springs, power springs, and etc.

● Our service and supply range:

We can assist in optimization your existing products, or the design application of newly designed products on constant force springs and power springs and etc.

We provide full range of materials in strip springs to meet all your spring needs.

Spring thickness: 0.04~3.0mm. (0.0015~0.12 in.)

Spring width: 2.5~80mm. (0.0984~3.1496 in.)

Materials: Stainless steels, High carbon and Medium carbon steels, and etc. Please contact us for further materials available.

Click here to contact our engineering support or to get an enquiry.

● Our main products:

Steel strip springs,

Stainless steel strip springs,

High carbon steel strip springs,

Precision steel strip springs,

Constant force springs,

Constant force extension springs,

Constant force compression springs,

Constant force torque springs,

Motor springs,

Power springs,

Prestressed power springs,

Spiral springs,

Carbon brush springs,

Force variable springs,

Torque variable springs,

Spring assembly,

Click here to find our main types of springs.

PRODUCTS

We specialized in manufacturing high performance Steel Strip Springs

Constant force spring

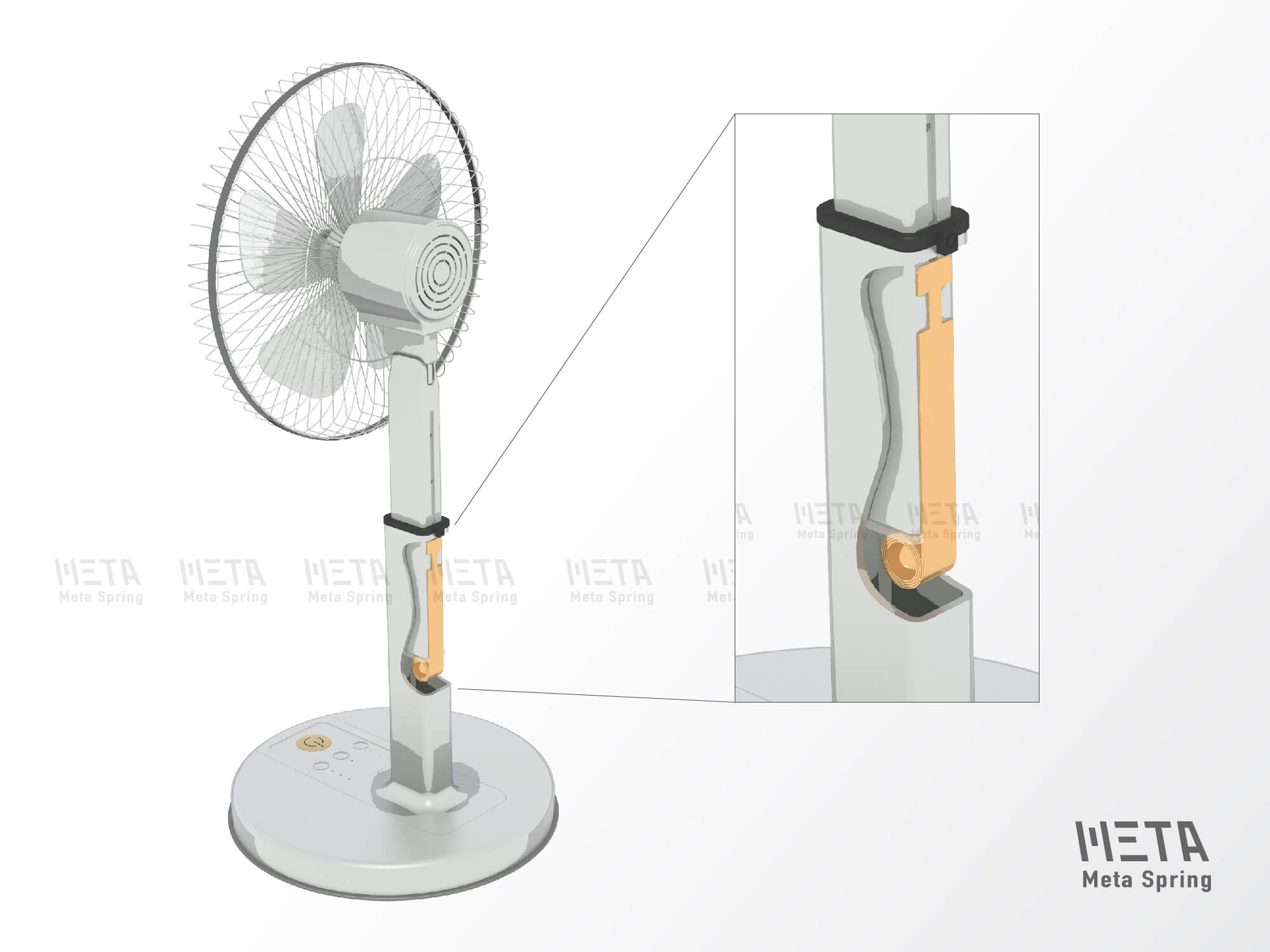

One of the features of the constant force springs is for the extension and compression applications required in various narrow spaces, especially for the long range operation mechanism.

Springs can be mounted on a spool or bushing or free running in a groove or cavity. Springs can provide increased force by connected/tandem, or combined layer by layer with minimal requirements of space extended.

Another characteristic of the constant force springs that with a very uniform and stable force-displacement traveled curve. Above are parts of the differences between constant force springs to wire compression and extension springs.

As a professional global market supplier, we Meta Spring Company manufactures and supplies the full range of Constant force springs, the range as below.

Spring width: 2.5~80mm

Spring thickness: 0.04 – 1.0 mm

Material: Stainless steel and Carbon steel

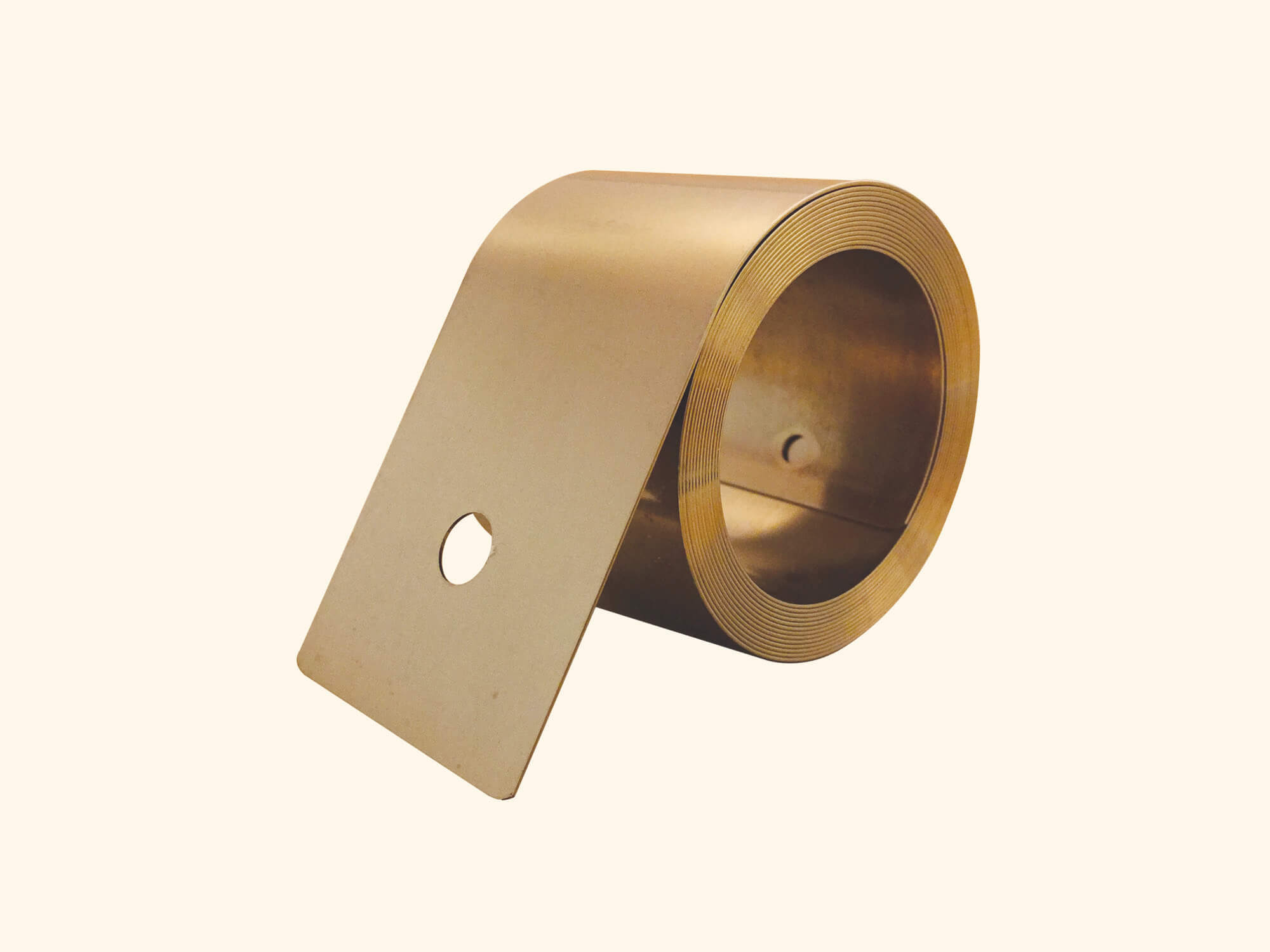

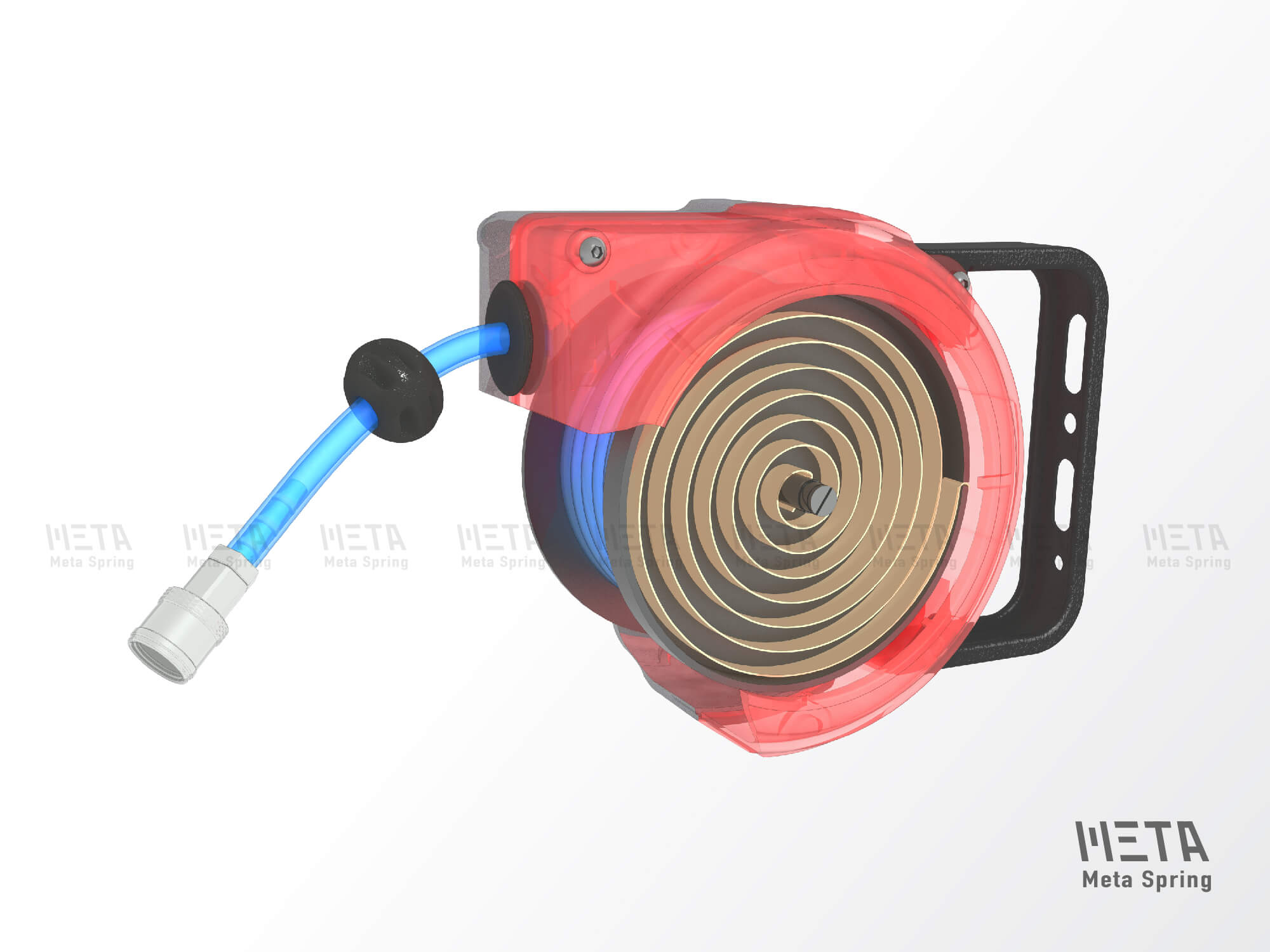

Power spring

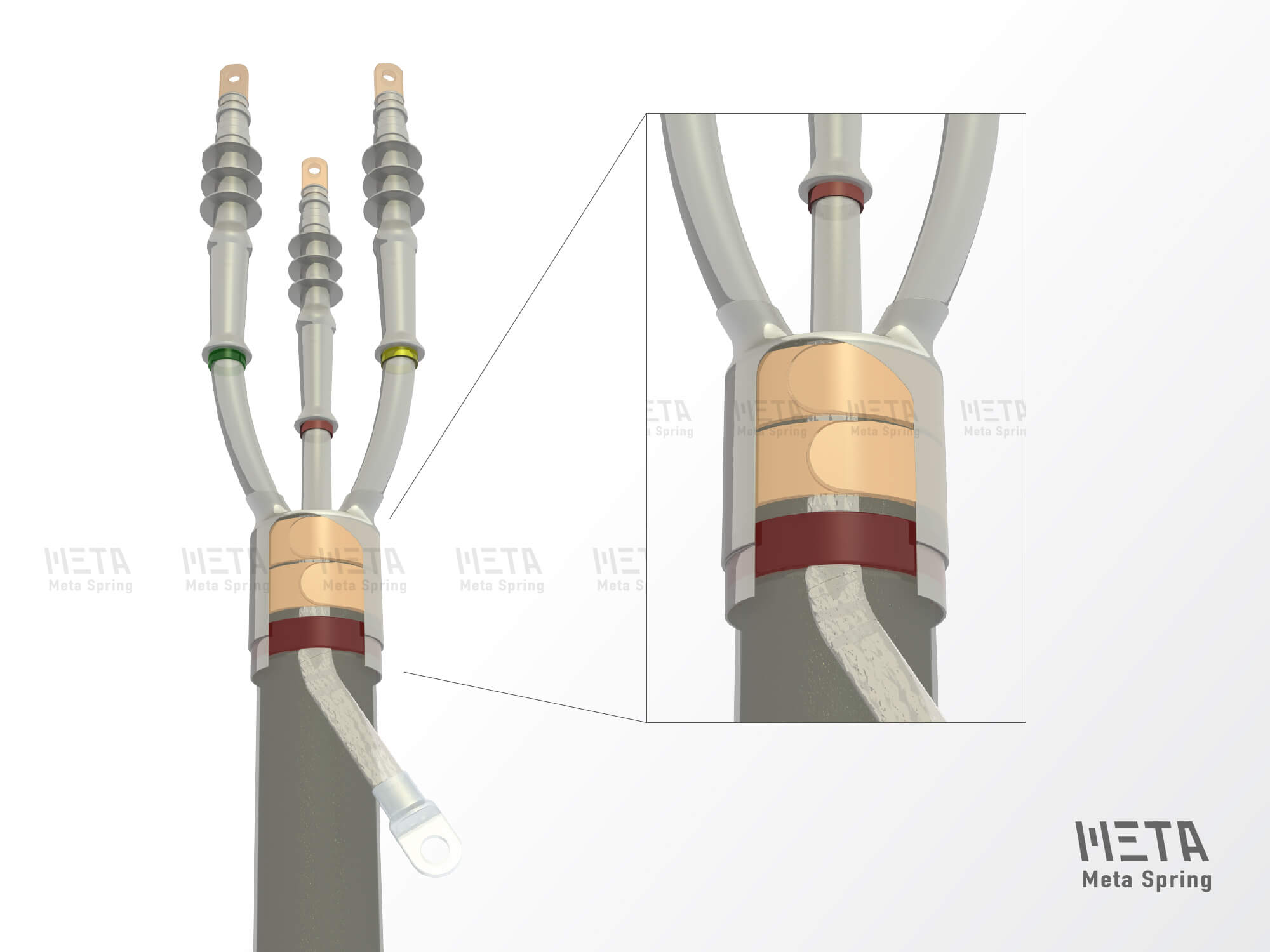

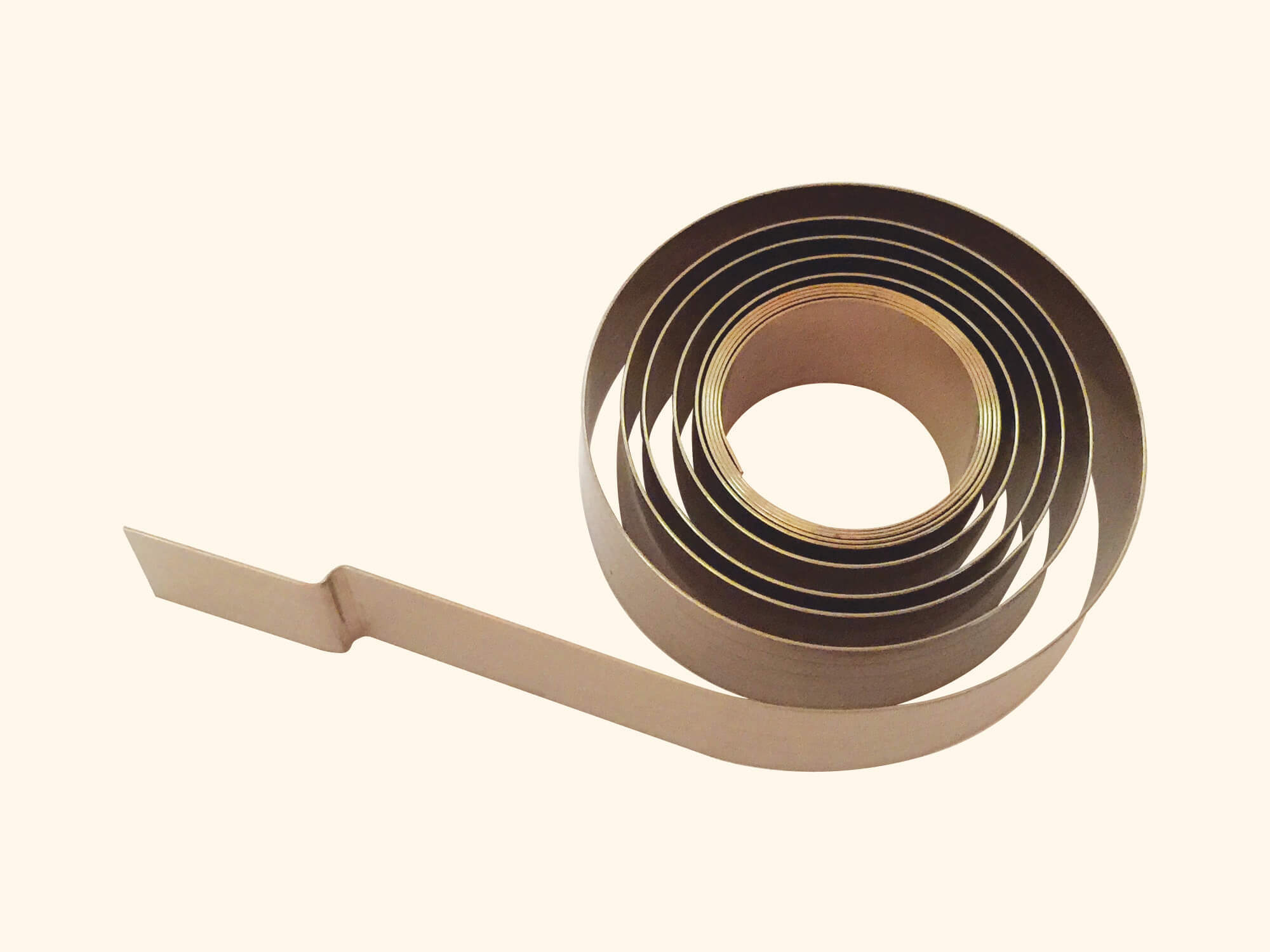

The classic power spring type are used in many industry applications. Usually be seen to the reel extension and retraction of power cables wires and air-hose, etc. The service life of classic power springs are very long, depending on the design. Power springs are used where space constraints and do not allow to use of prestressed type power springs, or where they are required by particular applications. Springs are flat wound with either retaining holes or bends on both ends that retained in some type of housing and connected to spools.

As a professional power spring supplier, we Meta Spring Company manufactures and supplies the full range of power springs, we develop our own spring coiling and processing equipments and spring assembly machines to ensure product stability and quality, the processing range as below.

Spring width: 2.5 – 80 mm

Spring thickness: 0.04 – 1.0 mm

Material: Spring strip steel, Stainless steel, Carbon steel

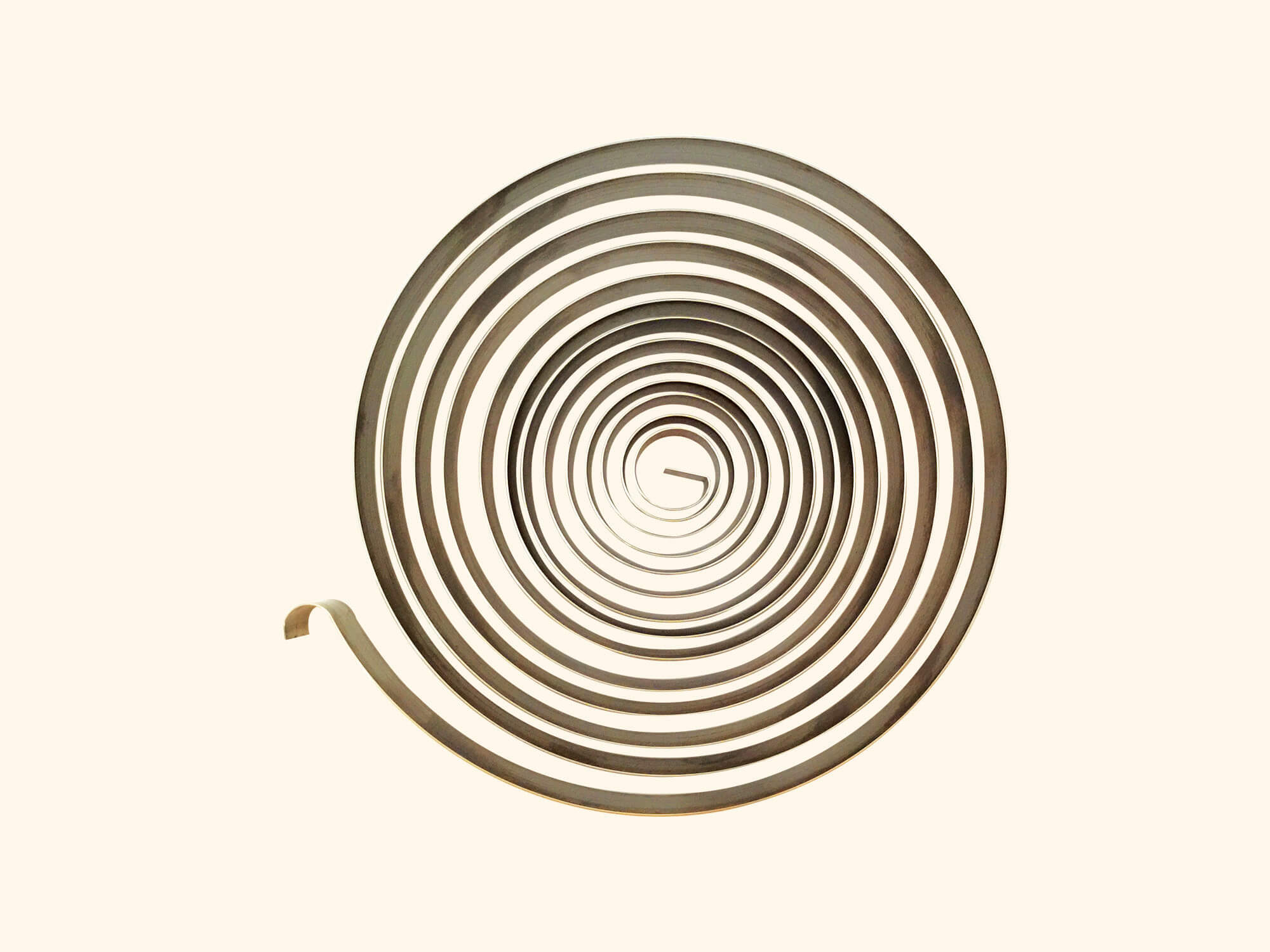

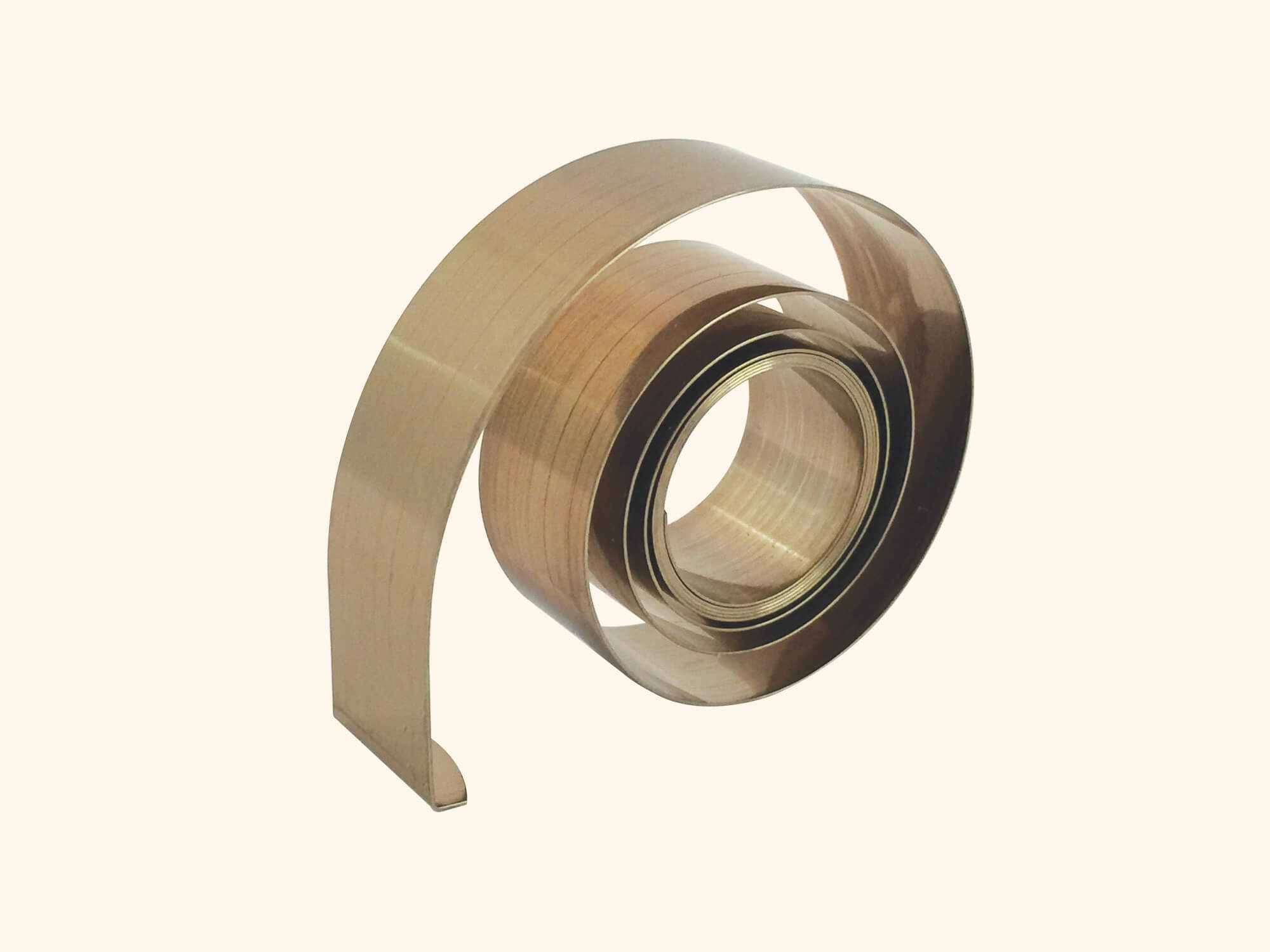

Pre-stressed type power spring

The design of prestressed type power spring is suitable for the needs of high torque applications and springs store from 25% to 55% higher torque than classic type power springs. Usually been seen on car seat belt assemblies. Springs are flat wound with either retaining holes or bends on both ends that retained in some type of housing and connected to spools as well. Spring appear in S-shape while spring fully unwound and in exposed free position.

We Meta Spring Company manufactures and supplies the full range of prestressed type power springs, we develop our own spring coiling and processing equipments and spring assembly machines to ensure product stability and quality, the processing range as below.

Spring width: 2.5 – 80 mm

Spring thickness: 0.04 – 1.0 mm

Material: Spring strip steel, Stainless steel, Carbon steel

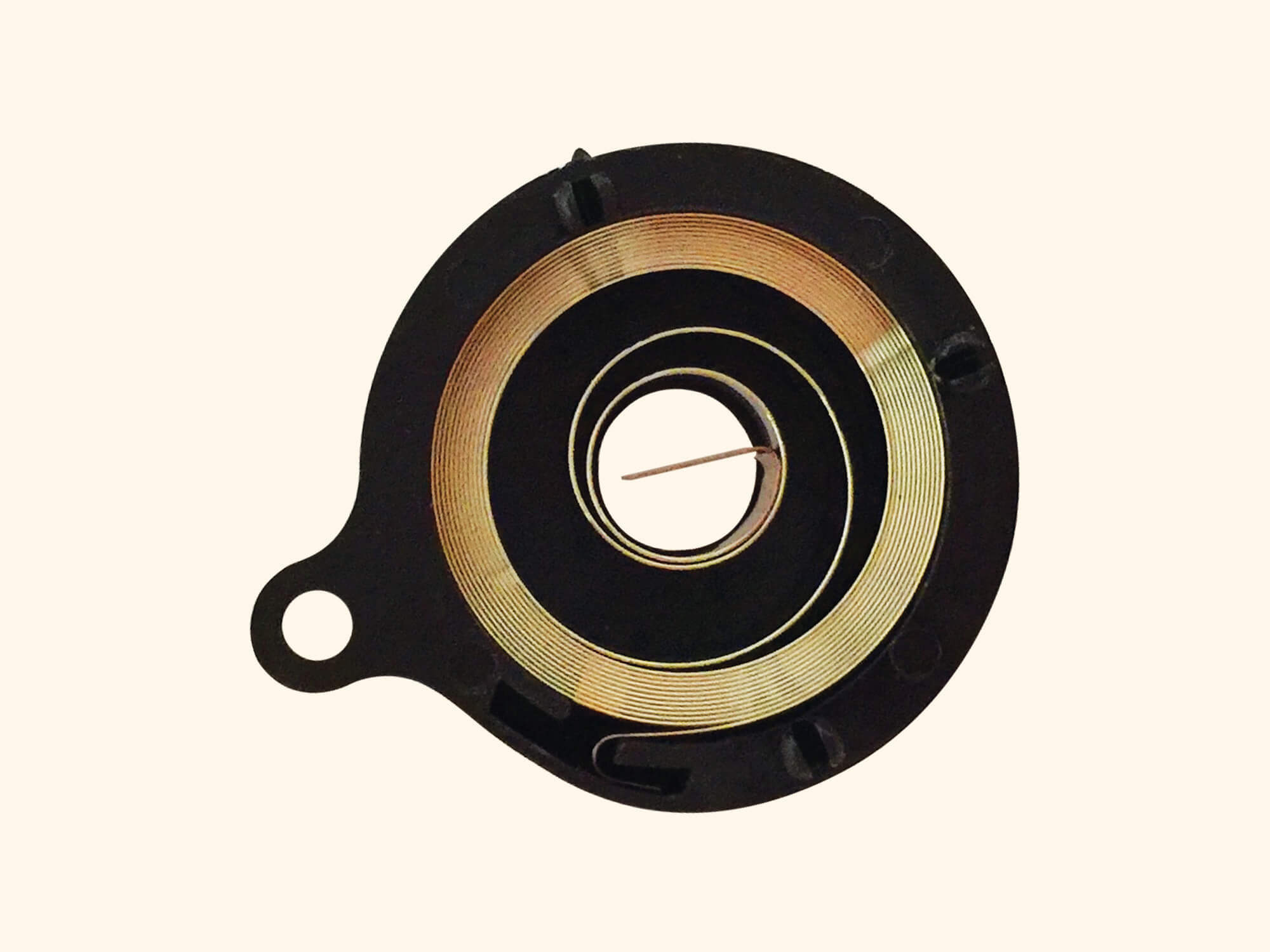

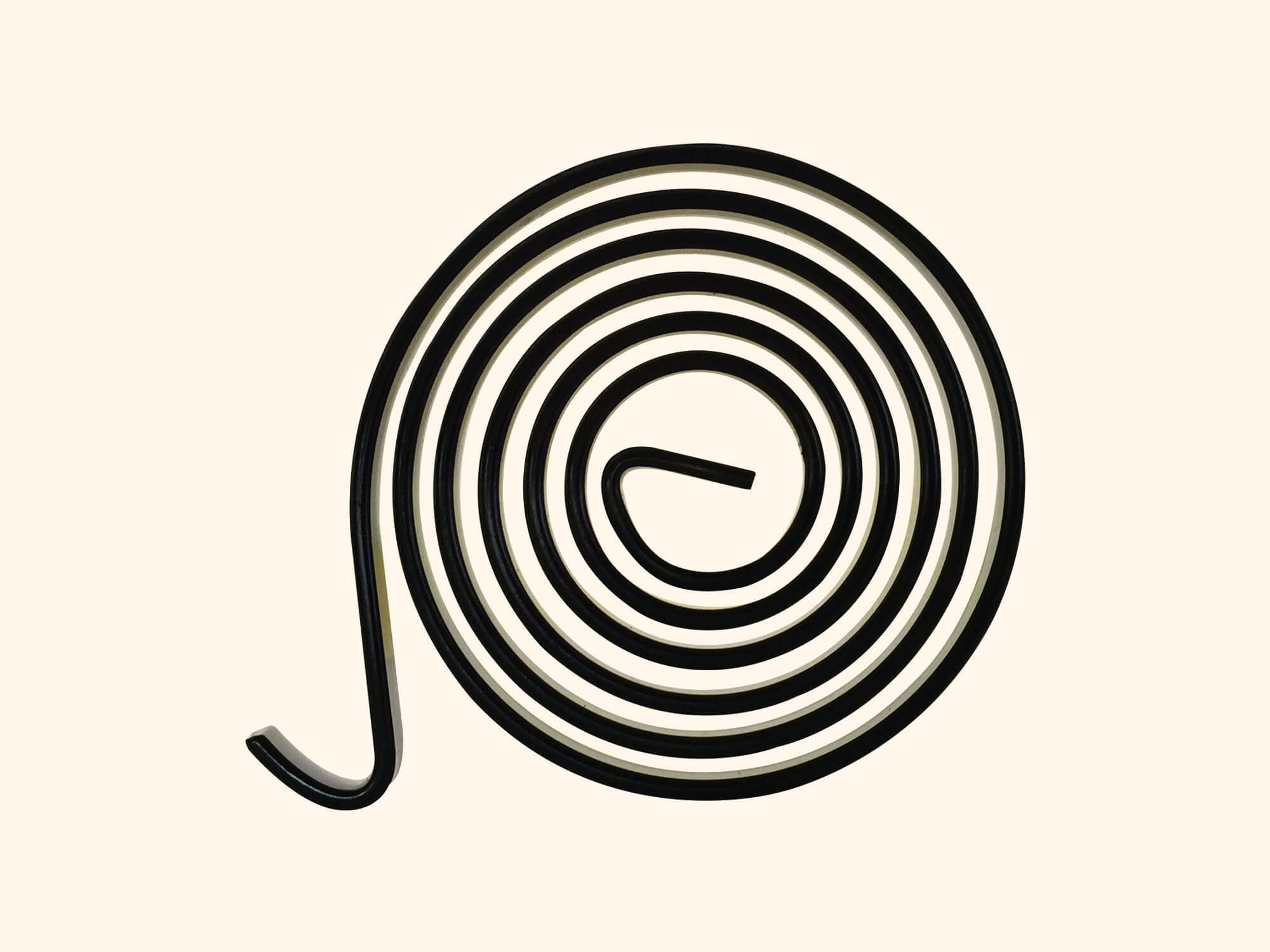

Spiral Spring

Spiral springs also known as clock springs or spiral torque springs, wound in flat state and each coil do not touched while in exposed free position. The spring inner end and outer end usually with a special bended shape. The inner end is fixed in position then to get the required torque by twisting the outer end to contact components while in working state. This type springs offer low frictions and the increase in the torque curve is almost linear when installed correctly and applications in smaller angles of rotation.

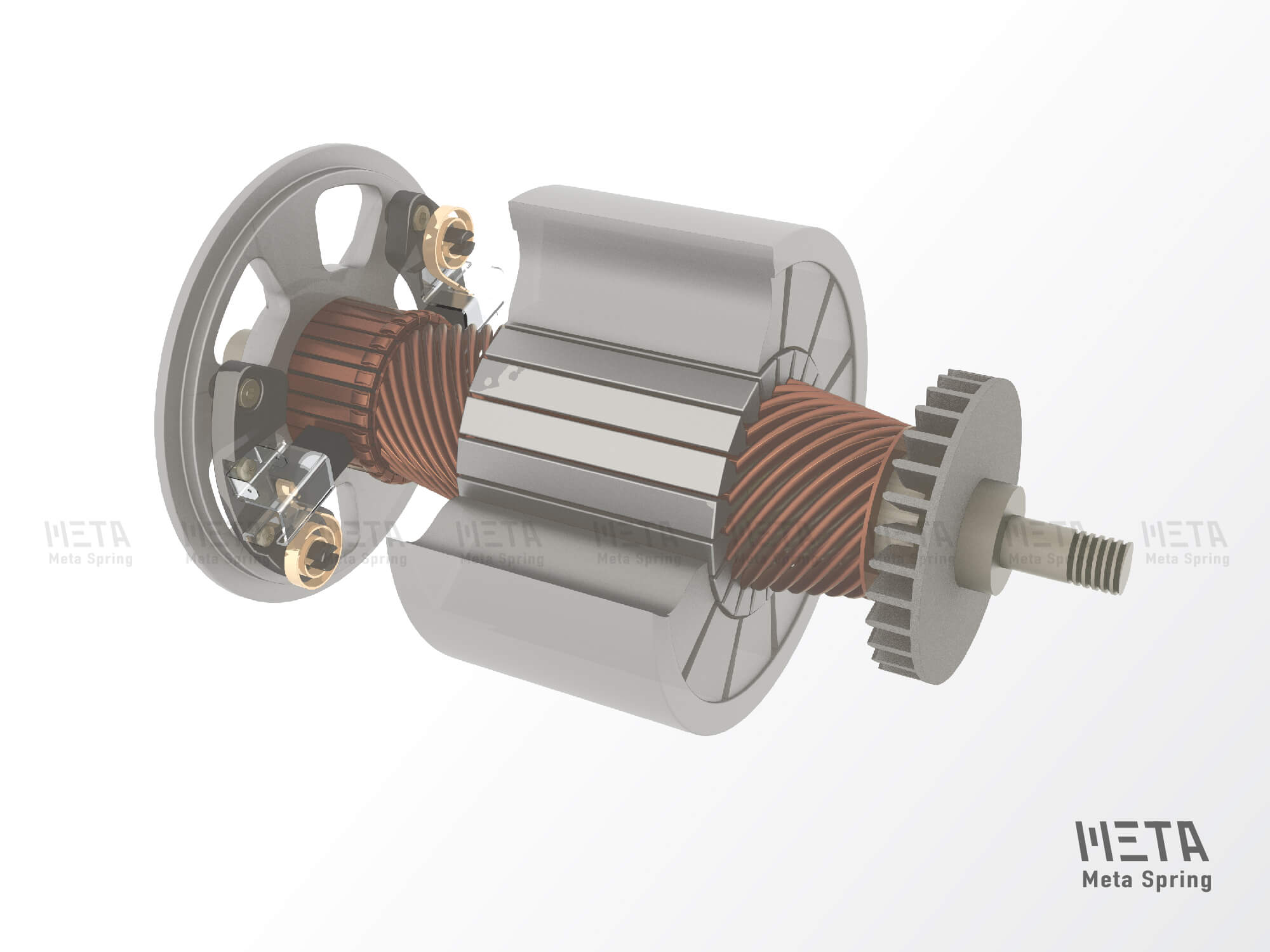

Spiral springs for carbon brushes, a key components of electric motors and generators, as well as applications in automotive window lift systems etc., we manufacture springs to meet your specific needs.

Spring width: 2.5 to 80 mm

Spring thickness: 0.04 to 3.0mm

Material: Carbon steel, Spring steel and Stainless Steel

Constant Force Torque Spring

(Motor Spring)

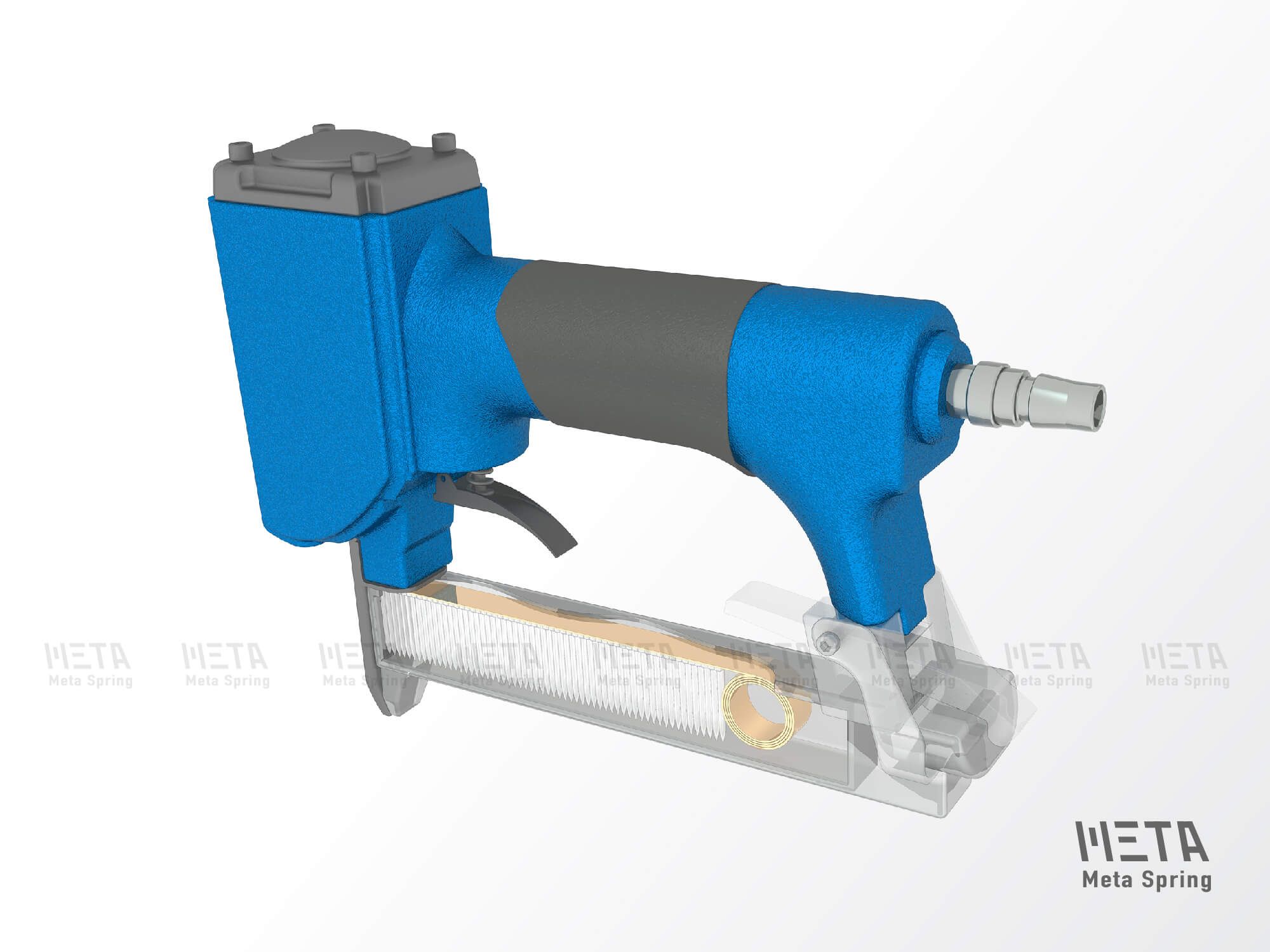

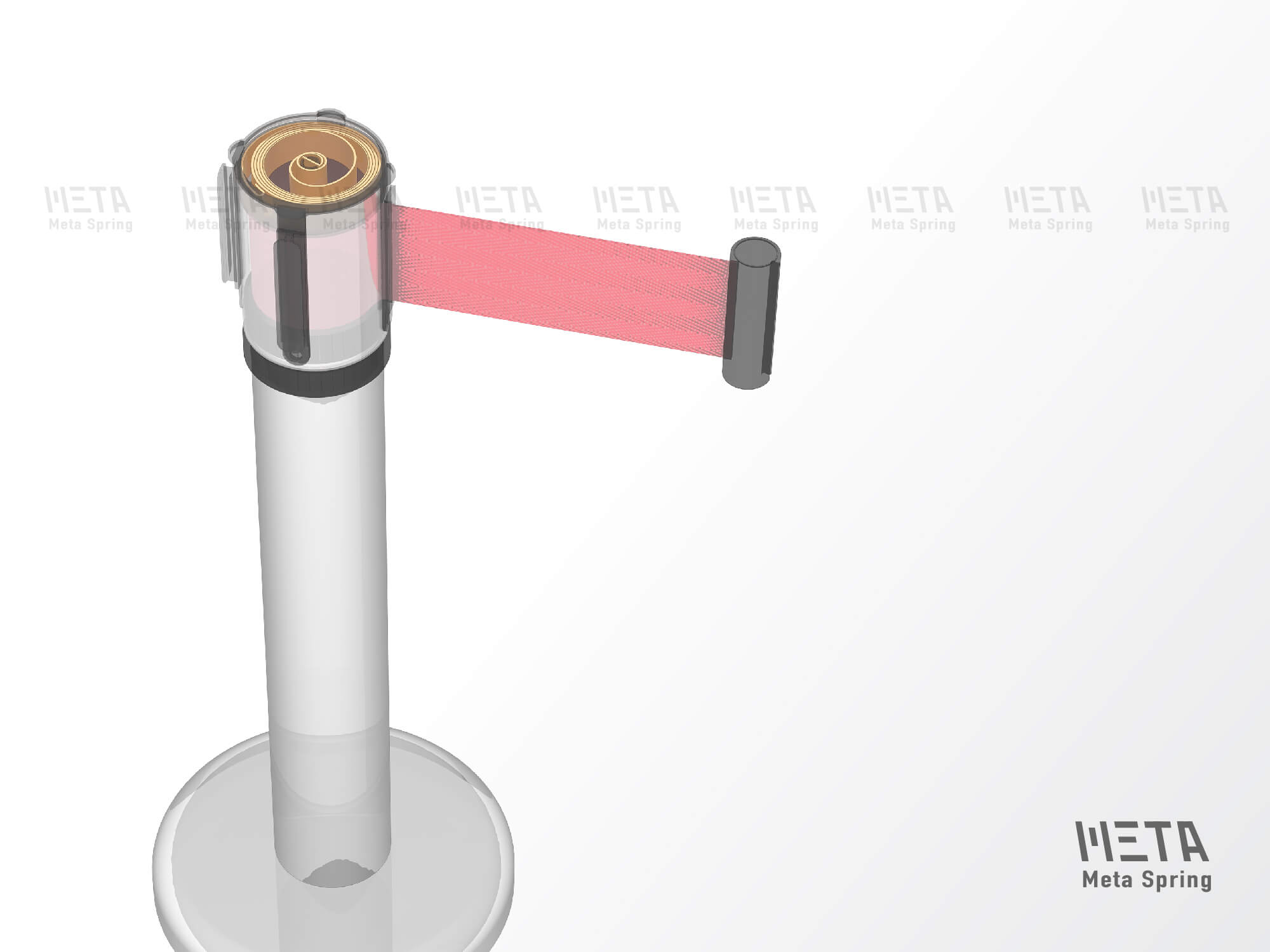

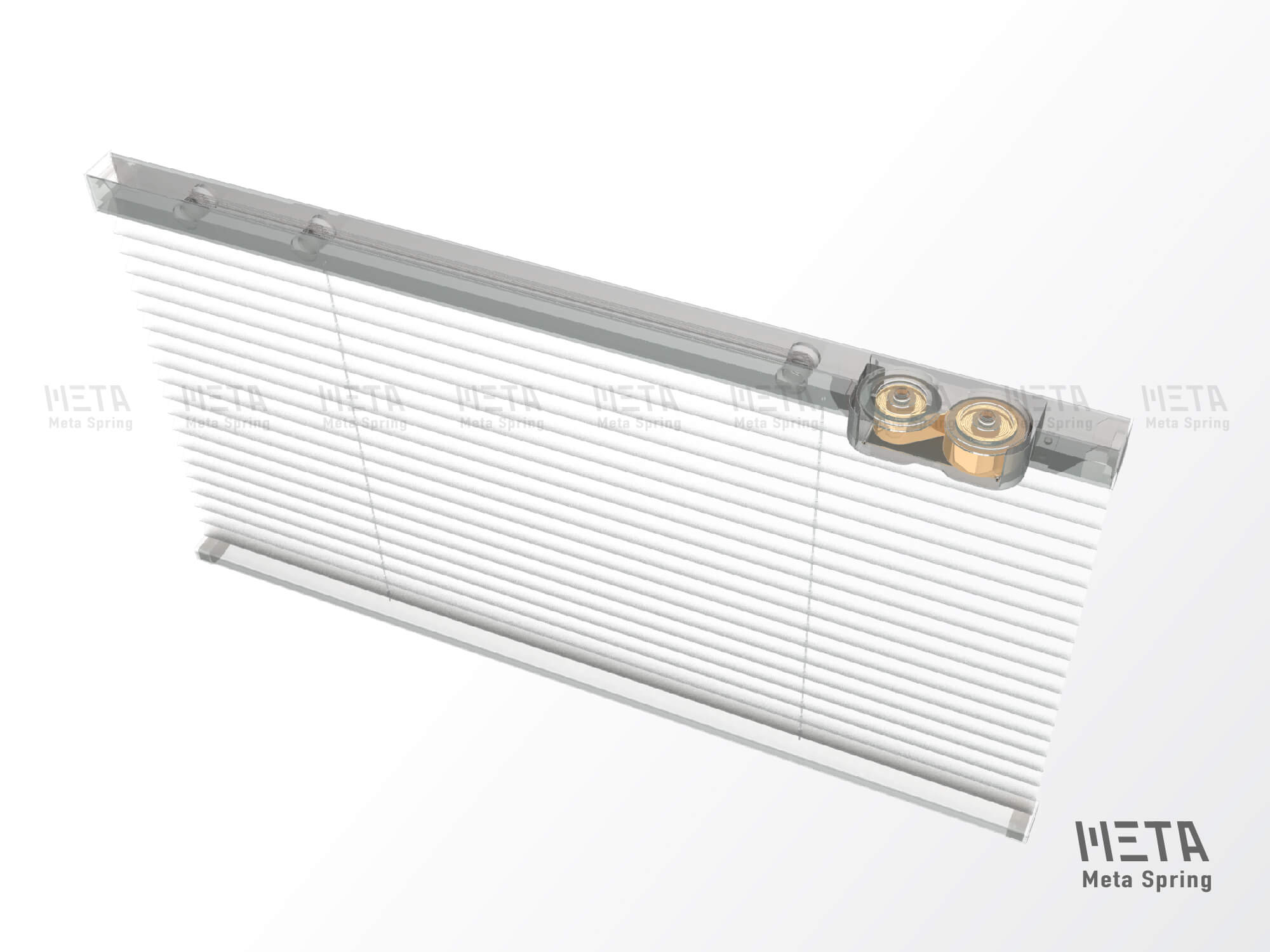

Constant force torque spring constructed from winding steel strip into strip coil and prestressed in a particular technical and, the feature of torque ensure identical torque across many rotation in its reversed direction. Constant force torque springs also called constant torque motor springs that provide high amounts of torque in a small construction.

The applications of constant force torque springs and its working structure usually arrangement into two axis, a output drum(or work drum) and the other called storage drum. Springs torque generate from rotate its reversed direction and returns into its original curvature on the storage drum while remove the loading. The spring provide rotational energy from the output drum, usually be used in linear motion together with using webbing or wire cable, or texture.

Stainless steel is typically used for most applications. Carbon steel and other materials may be required. A wide variety of materials are available for use depending on your application.

Spring width: 2.5~80mm

Spring thickness: 0.04 – 1.0 mm

Material: Stainless steels and Carbon steels

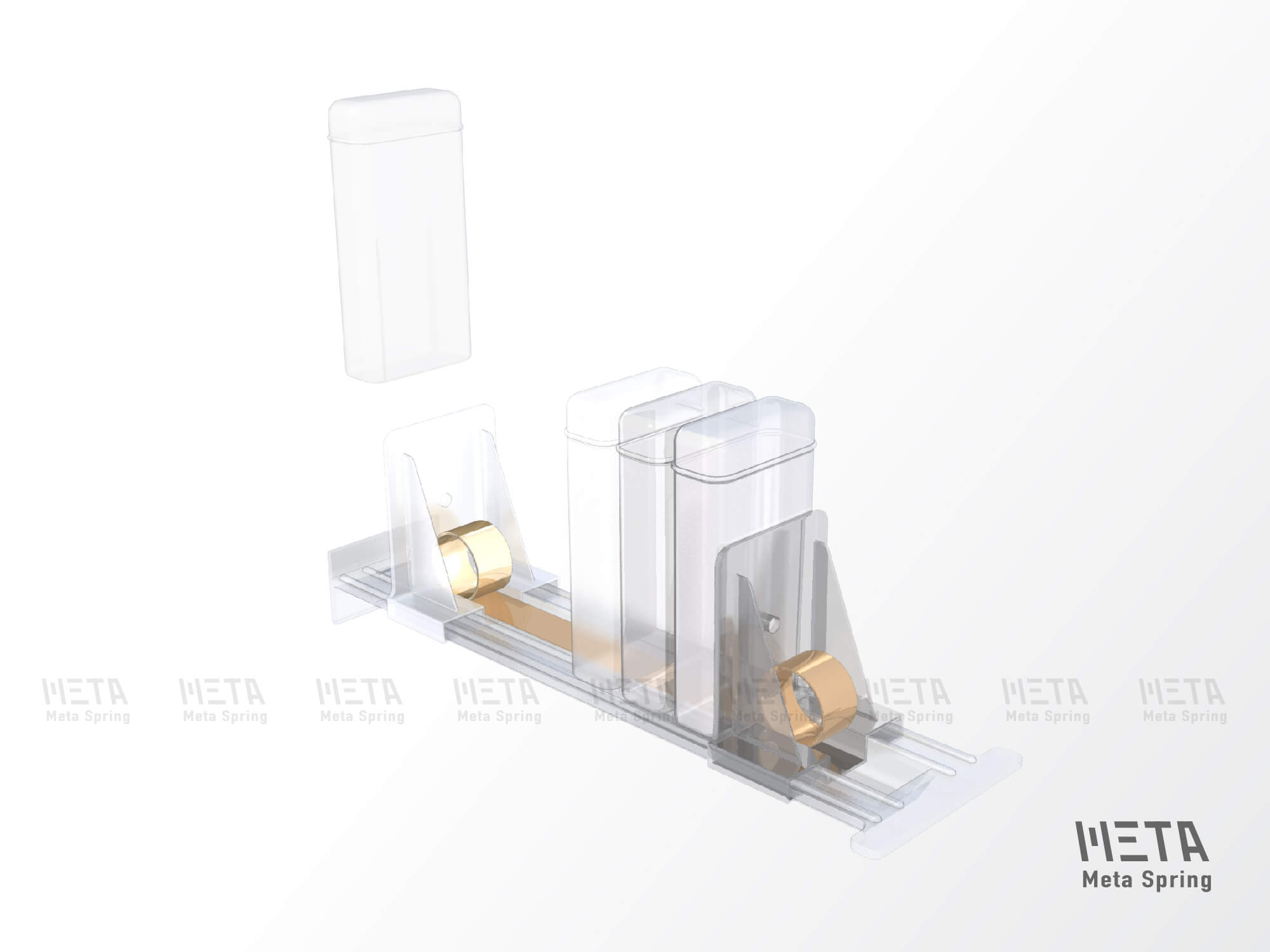

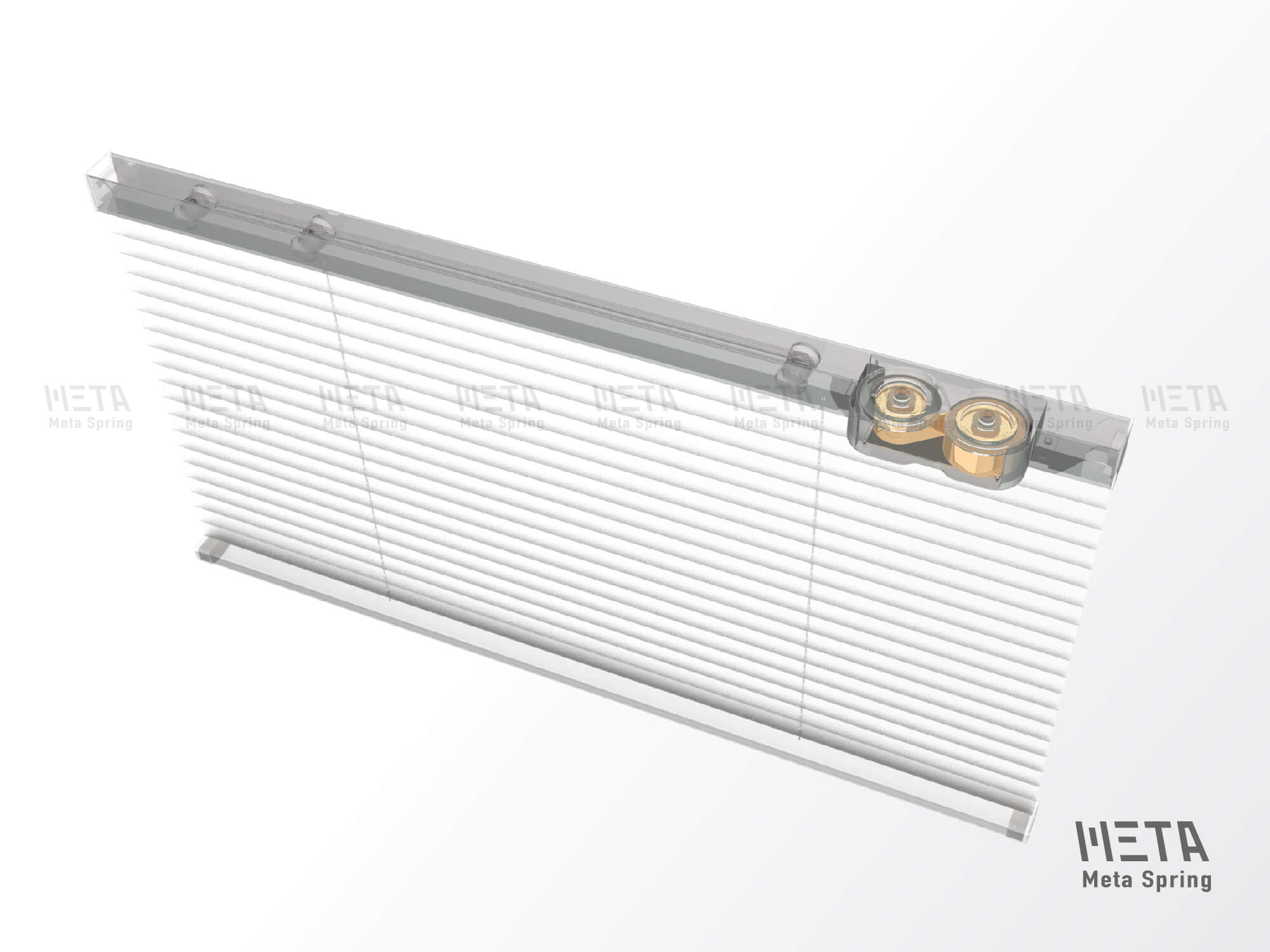

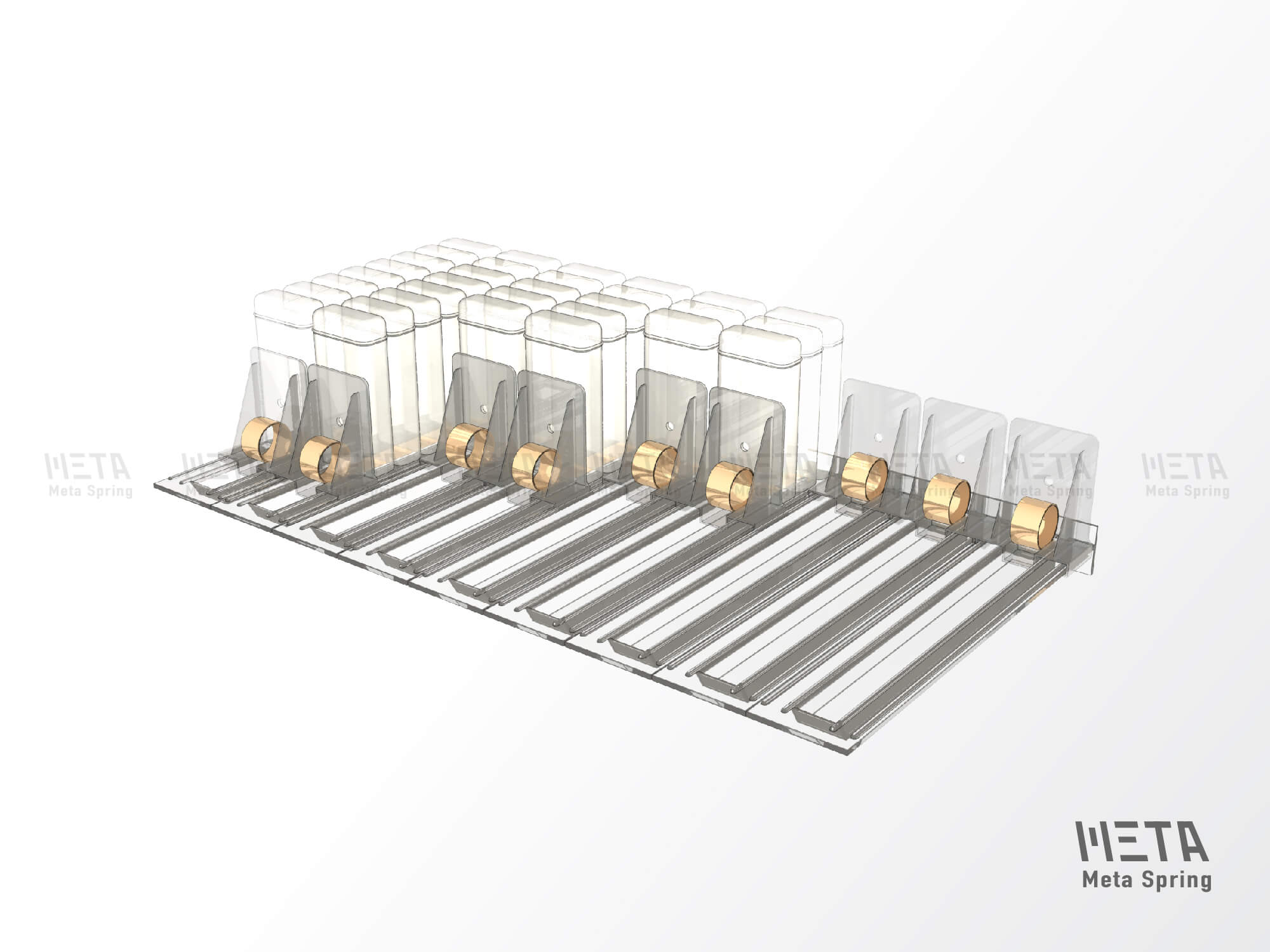

Variable Force Spring

Variable force spring also named variable torque spring, the application are similar to constant force spring in extension and compression applications. The diversification combinations of force and torque is the feature of variable force spring.

Variable force spring is constructed with the similar characteristic of constant force type spring, and spring provide variable force or variable torque by adjust the force-displacement traveled curve within material limits to meet particular applications. Hence the torque and force can be combine with negative gradient and positive gradient in one spring. We internally developed and manufactured the equipments for production this special spring types.

The point of purchase display track and cordless window shades are kind of common applications.

There are diversification combinations and solutions in applications of force and torque designed available, therefor we suggest contact and get the reference with our engineer as early as in its design period.

Spring width: 2.5~80mm

Spring thickness: 0.04 – 1.0 mm

Material: Stainless steels and Carbon steels